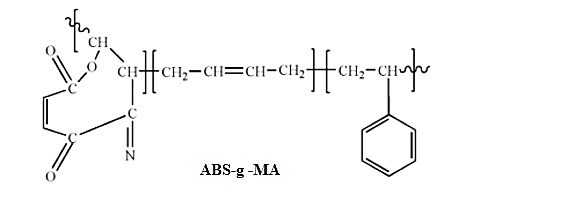

Maleic Anhydride Grafted ABS (Aria Couple ABS-g-MA)

Aria couple 1732 is a maleic anhydride modified Acrylonitrile Butadiene Styrene (ABS) (ABS Compatibilizer or Maleated ABS) . It has been primarily designed to act as a compatibilizer in ABS compounds such as ABS/GF, ABS/PC, ABS/PA and ABS/PET to achieve good mechanical properties. As a suitable compatibilizer, Aria couple 1732 has a significant effect on the notched Izod impact strength of the alloys and also has a slight effect on the other properties such as tensile strength, flexural strength, and vicat softening temperature.

ABS is a common thermoplastic polymer comprised of three monomers: acrylonitrile, butadiene and styrene.

Compositions of the diverse monomers can be controlled to achieve the requirements of a variety of applications. This polymer is characterized by notch insensitivity, easy processability, relatively low cost and high impact and chemical resistance that widely appears in parts of TV or computer equipment. However, the overall mechanical properties of ABS are lower than those of most engineering plastics, and the heat distortion temperature (HDT) of general grades of ABS is lower than 100°C. In order to upgrade the use of ABS, one simple way is to blend ABS resin with other high performance engineering plastics such as polycarbonate (PC), polyamide (PA), etc.

PC and other engineering thermoplastics such as nylon can contribute towards improvements in strength, dimensional stability, impact resistance and heat distortion temperature of the finished parts. On the other hand, ABS offers chemical resistance, processing advantages besides cost reduction with respect to PC. Therefore, the purpose of blending of ABS with PC is to improve the mechanical properties and overall performances with respect to the neat polymers. The experimental tests show that this blend has a better balance of properties despite the lower price. Actually ABS/PC blends have become widely applicable in home appliances, automobile and computer fields due to their relatively good mechanical properties, processibilty, and heat resistance. An ABS/PC blend can be blessed with a relatively high impact strength when the PC component is rich. To reduce the material cost, an ABS/PC blend with a high loading of ABS is favorable. Blending PC with high-loading ABS will not apparently compromise the good tensile strength, flexural strength, and high Vicat softening temperature of a PC/ABS blend. But the impact strength of an ABS/ PC blend is very low, even lower than that of pure ABS. Generally, this unexpected result arises from the poor compatibility of an ABS/PC blend. Therefore, how to improve the compatibility of an ABS/PC blend is a challenge to be solved. Aria Polymer Pishgam has offered a good solution for this problem. Our research on multicomponent polymer blends has focused on the techniques of reactive blending of immiscible polymers.

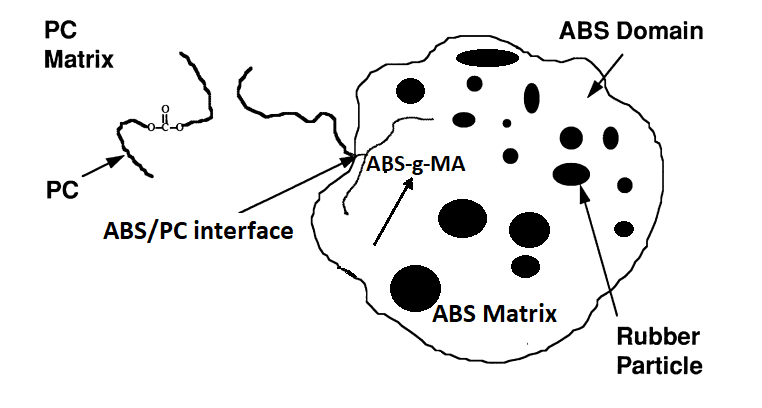

For many polymer blends, the low compatibility of their components due to high difference interfacial tension, very low interfacial adhesion and different viscosity between the two phases is one of the biggest challenges. Generally, the interfacial adhesion of immiscible and incompatible blends is not strong enough because the interfacial tension of the blend components is very high.

Indeed, there is one chemical reaction or more between the blending components with reactively functional groups during the blending process at high temperature. The reactions can in situ generate compatibilizers that act as interfacial agents to reduce interfacial tension and promote interface adhesion. This technique should be fast and irreversible because it has been well demonstrated as being effective in some commercialized blends such as ABS/PC.

Therefore in order to increase compatibility between two phases such as ABS/PC or other compounds the addition of compatibilizer is very important.

The notched Izod impact strength is one of the most important properties for rigid polymers such as the ABS/PC blend because of their notch sensitivity. Aria couple 1732 (Maleated ABS) is a good compatibilizer and tremendously improves the impact strength of the ABS/PC blend.

The notched Izod impact strength is one of the most important properties for rigid polymers such as the ABS/PC blend because of their notch sensitivity. Aria couple 1732 (Maleated ABS) is a good compatibilizer and tremendously improves the impact strength of the ABS/PC blend.

- The impact strength of the ABS/PC blend can be greatly enhanced by addition of small amount of Aria couple 1732;

- The flexural strength of ABS/PC modified by Aria couple 1732 is vividly higher than that of the only ABS/PC blend at a given PC content.

- The tensile strength of ABS/PC modified by Aria couple 1732 and non-modified ABS/PC blends are almost the same at a given PC content, which implies that Aria couple 1732 has no negative impact effect on the tensile strength.

Consumption of Aria couple 1732 reduces the interfacial tension as well as the particle size of dispersed phase resulting in an improvement of interfacial adhesion. Adding Maleated ABS into different ABS/PC compounds slightly changed the ratio of the plastic phase components (polystyrene, acrylonitrile-styrene) to the rubbery phase component (polybutadiene, butadiene-styrene, butadiene acrylonitrile) altering the interaction between these phases. This indicates that viscous components of the blends could be changed, since Aria couple 1732 has a similar ABS basic component.

Maleated ABS of Aria Polymer Pishgam Company

Applications

- Aria couple 1732 functions as a coupling agent between reinforcing materials such as glass fiber and ABS to achieve good mechanical properties.

- Aria couple 1732 causes effective compatibility between ABS/PC, ABS/PA and ABS/PET to reach high mechanical and thermal properties.

- Aria couple 1732 improves interfacial properties recycled PC and ABS.

Feel free to be in touch with us for purchase or any advice.

📲 +989120701632