Top 10 Injection Molding Defects (second part)

Top 10 Injection Molding Defects (second part)

Injection molding efficiency is more focused on multiple process and machine parameters that dictate the quality of the final product in terms of multiple output responses. It is important to state that precise optimization of various input parameters is very important to achieve the desired quality indicators. Five of the most common defects of the injection molding process were reviewed in the first part of the article. Five more of the most common quality defects related to injection molding, the factors that cause them, and the actions that can be taken to fix them, will be investigated in this article.

Introduction

Injection molding is one of the most widely used methods of producing parts and products. The method is fast, works with a variety of plastics, and can result in a prototype or finished product that is both durable and highly detailed. But this process is complex and full of challenges. Fortunately, many of them are easily solvable [1]. Injection molding defects are often caused by process problems. Some molding defects may be difficult or expensive to fix, but most of these defects can be prevented without having to redesign the mold tool or replace other production equipment by adjusting the molding process. Usually, these defects can be avoided relatively easily by adjusting the flow rate, temperature or pressure of mold.

Common defects in injection molding

-

Flash

This means that there is excess plastic on the part of the mold separator or ejector. Flash, also called spew or burrs, is a large amount of molding material that appears as a thin edge or ridge on the edge of a component. A flash defect occurs when material has flowed out of the intended flow channels and into the space between the tool plates or into the injector pin. An injection molding flash defect is usually subtle, but if it is particularly evident in a product, it may be considered a major defect. The process of reworking a flash-molded product often involves cutting off excess material.

Fig. 1. Flash defect in injection molding [2]

- Insufficient clamping force

- Mold defect (not locking the mold)

- Improper design

- Excessive injection pressure and temperature

Solutions:

- Proper design of the template

- Cleaning the mold surface

- Increasing the time and reducing the injection speed

- Reducing the temperature of the nozzle

- Reduction of injection pressure

-

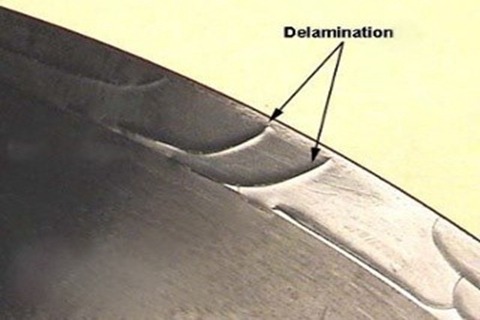

Delamination

If the thin layers on the surface of a molded part easily separate the underlying material, leading to peeling of the underlying material, it is a molding defect called delamination. This defect is considered as a relatively serious defect because it reduces the strength of the part.

Fig. 2. Delamination defect in injection molding [3]

- Mixing incompatible polymers

- Excessive humidity

- Valve and flow path have sharp angles.

Solutions:

- Not using a lot of recycled materials

- Try to avoid the impurities in the materials

- Chamfering sharp corners

- Increasing the mold temperature

- Dry the material properly.

-

Short Shot

It is a phenomenon in which mold cavities cannot be completely filled. Short shot occurs when the flow of molten material does not completely fill the cavities of a mold. The result is that the molded part is incomplete after cooling. A short shot may appear as incomplete compartments on plastic display shelves or missing prongs on a plastic fork. Short shots are usually classified as a major defect that can affect the performance or appearance of the molded manufacture.

Fig. 3. Short shot defect in injection molding [4]

- Mold temperature, material temperature or pressure and injection speed are too low.

- Uneven plasticization of raw materials

- The part is too thin or the valve size is too small.

- Premature curing of molten polymer due to improper structure design

Solutions:

- Choosing plastics with lower viscosity or higher MFI

- Increasing the temperature of the mold and materials to increase flowability

- Changing mold design so that the gas is not trapped inside the mold and is properly discharged.

- If the maximum material feed is reached, increase the material feed in the molding machine or use a machine with a higher material feed capacity.

-

Weld Lines

There are seams that appear in the place where two areas of molten plastic meet. Weld lines can appear on the surface of a molded part where the molten material has converged after being split in two or more directions in the mold. A hairline-like weld is the result of poor material bonding, which reduces the strength of the product.

Fig. 4. Weld lines defect in injection molding [2]

- If there are holes, inserts, or multi-gate injection molding methods in the manufactured parts, or if the wall thickness of the parts is uneven, weld lines may occur.

Solutions:

- Rising mold or molten plastic temperature

- Increasing injection speed

- Using polymers with lower viscosity or melt temperature

-

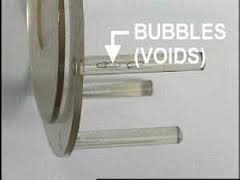

Vacuum Voids

Vacuum voids are air bubbles that are trapped in or near the surface of an injection molded part. Quality control professionals usually consider voids to be a minor defect, but larger or more voids can in some cases weaken the molded part because air exists below the surface of the part where the molded material should be.

Fig. 5. Vacuum voids defect in injection molding [2]

- Not filling the form completely

- Poor mold ventilation, especially around ridges

- Improper location of the port

- Very fast filling speed (trapped air creates short shots)

- Improper mold temperature

- Excessive part thickness (more than 6.3 mm (1.4 in))

- Trapped moisture

- Air entrapped through porous or ultrafine air-absorbing additive powders

Solutions:

- Placing the port in the thickest part of the mold

- Using plastics with lower viscosity. This ensures that less gas is trapped because the air can exit faster.

- Increasing maintenance pressure as well as maintenance time

- Ensuring that the mold parts are perfectly aligned [2].

Final Word

If injection molding is not done correctly, costly errors can occur. Quality problems in finished products can range from some minor surface issues to some serious defects that may even compromise user safety. Also, such defects can affect the performance and quality of the product. As a result, customers may stop buying from a particular brand. Therefore, it is very important for plastic mold makers to ensure that the process is done without any errors. In this article, we discussed some of the most common problems and common solutions of advanced injection molding.

In order to investigate the defects of the injection process in the polymer industry, contact the experts of Aria Polymer Pishgam company.

Author: Emad Izadi Vasafi

References:

- Kashyap S, Datta D. Process parameter optimization of plastic injection molding: a review. International Journal of Plastics Technology. 2015 Jun;19(1):1-8.

- https://www.creativemechanisms.com/blog/what-cause-injection-molding-defects-and-how-to-fix-them

- https://waykenrm.com/blogs/plastic-injection-molding-problems-and-solutions/

- https://www.plasticmoulds.net/troubleshooting-product-defects.html