Effect of Adding Grafted Polypropylene by Maleic Anhydride on Properties of Polypropylene/Talc Composites

Effect of Adding Grafted Polypropylene by Maleic Anhydride on Properties of Polypropylene/Talc Composites

Polypropylene has numerous benefits such as: low cost, suitable mechanical properties, excellent and chemical and moisture resistance. Moreover, it can be used in various applications like pipe industry, cable, fibers, packing, automotive, sheets and etc.[1]. Also Using a mineral filler such as talc can help decrease the product cost, increase mechanical properties, improve dimensional stability and increase resistance to deformation. The determining factor in the effective performance of talc particles in the polyolefin matrix is making an effective interaction between talc and the polymer matrix and their uniform distribution within the polymer[2]. Due to polar nature of talc and non-polar nature of PP and PE and insufficient compatibility between these two, use a compatibilizer which can improve the interface between filler and matrix, is essential. The most important compatibilizer for improving interaction between carbonate calcium and polyolefin matrix is used, is grafted polypropylene or polyethylene by maleic anhydride (PP/PE-g-MA). PP/PE-g-MA due to its both polar and non-polar parts can make a strong polymer-filler network[3].

Effect of adding PP-g-MA on the mechanical properties of PP/Talc composites

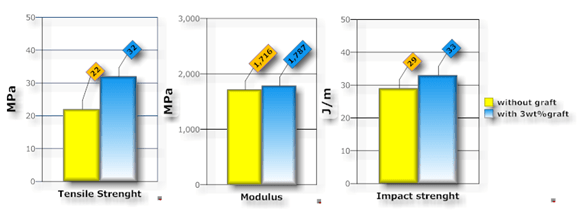

Grafting by increasing the compatibility between PP and talc leads to improving the mechanical properties of PP/Talc composites[4]. For example, adding 3%wt of graft to PP/30%Talc cause increase the tensile strength, modulus, and impact strength. (Figure1)

Fig. 1. Effect of grafting on mechanical properties of PP-Talc composite

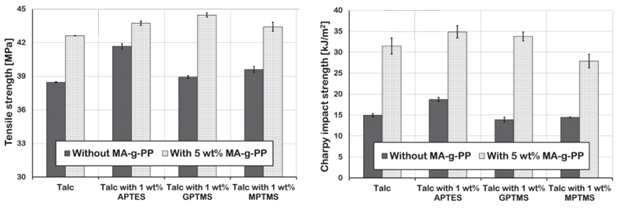

Graft has a similar effect on composites containing higher percentages of talc. As in PP/50%Talc composites, as shown in Figure 2, the tensile strength and impact strength increased significantly after the addition of 5%wt grafts.

Fig. 2. Effect of grafting on mechanical properties of PP-Talc compound

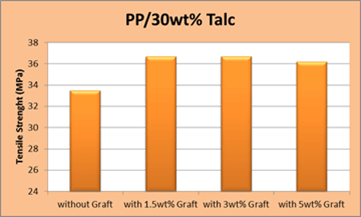

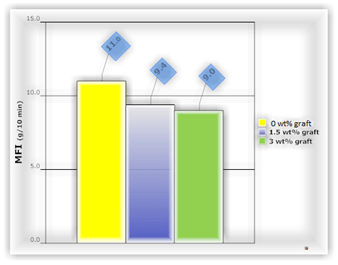

By considering the fact that in industry, the cost of products is always important, so a compatibilizer with a low optimum percentage will be able to use in industrial consumption. By adding PP-g-MA high-quality and affordable composites can be produced because its optimal percentages are usually low amounts. For example, at PP/30%Talc composites the optimum graft percentage has been reported 1.5%. (Figure3)

Fig. 3. The optimum amount of Graft in the PP/Talc compound

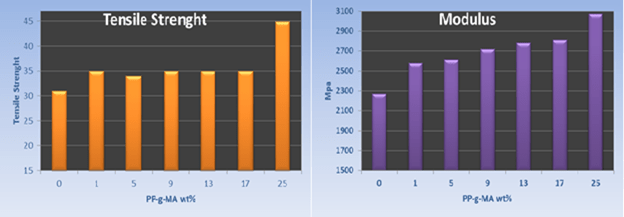

As it is shown in the Figure4, increasing the percentages of grafts until 25% has not remarkable effects on composite properties.

Fig. 4. Effect of grafting on tensile strength and modulus

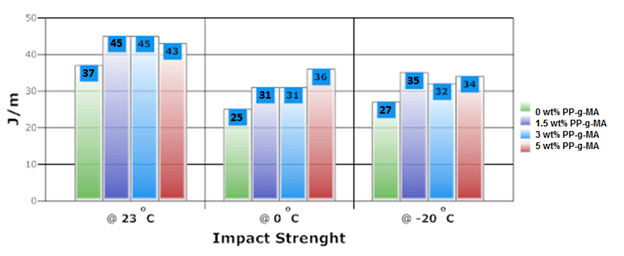

Since, one of the weaknesses of PP is its fragility at low temperatures, effect of grafting on impact strength of PP/30%Talc at 0oC and -20oC has been investigated. As it is shown in Figure5, samples which contain different percentages of grafting has higher impact strength than the samples without grafting[5].

Fig. 5. Effect of grafting on impact strength

Effect of adding PP-g-MA on rheologic properties of PP/Talc composites

Adding PP-g-Ma to PP/Talc composites, leads to improve flowability and rheologic properties[6].

Addition of PP-g-MA to PP / Talc composites improves flowability and rheological properties, so that the melt flow index (MFI) of PP/30%Talc composites reached 9.4 and 9 g/10min, respectively, by adding 1.5 and 3% grafts, respectively. (Compared to 11 for PP/30%Talc composites without grafts).

Fig. 6. Effect of grafting on processing of PP/Talc

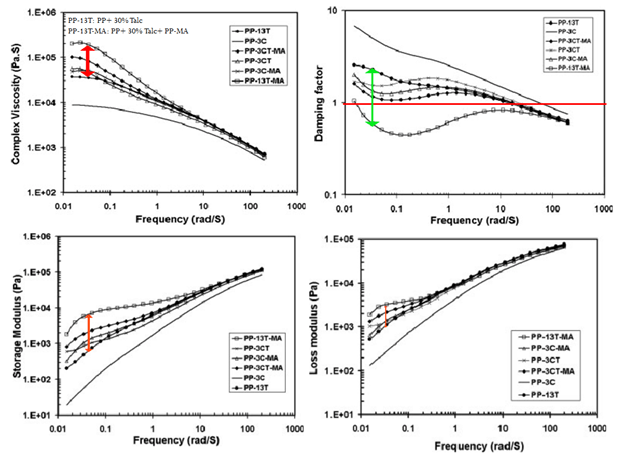

Addition of graft according to increasing the interaction between polypropylene and talc and make as strong network of polymer-filler also can improve the rheologic properties of composites. As all three rheological parameters of complex viscosity, storage modulus and loss modulus of composites showed a significant increase after graft addition. As Figure 7 shows, by adding a graft to the PP / Talc composite, the loss factor is significantly reduced to less than one, resulting in an increase in the elasticity of the system due to better interaction between the polymer and the filler.

Fig. 7. Effect of graft on rheologic properties of polypropylene/talc

Effect of addition PP-g-MA on morphology of PP/Talc composites

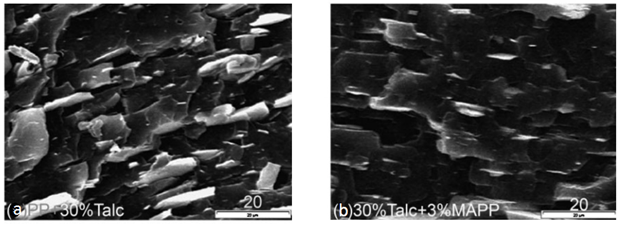

The morphological images of talc particles in the PP matrix confirm the mechanical and rheological properties of its composites[7]. Figure 8 shows the distribution morphology of talc particles in PP / 30% Talc composites before and after the addition of 3% graft. After adding 3% graft, the distribution of talc particles has become much more uniform.

Fig. 8. Effect of grafting on the PP/Talc morphology

Comparison of PP / (PP-g-MA) / Talc composites with commercial sample of PP / Talc composites used in automotive industry

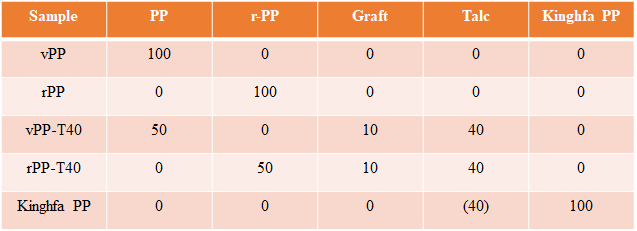

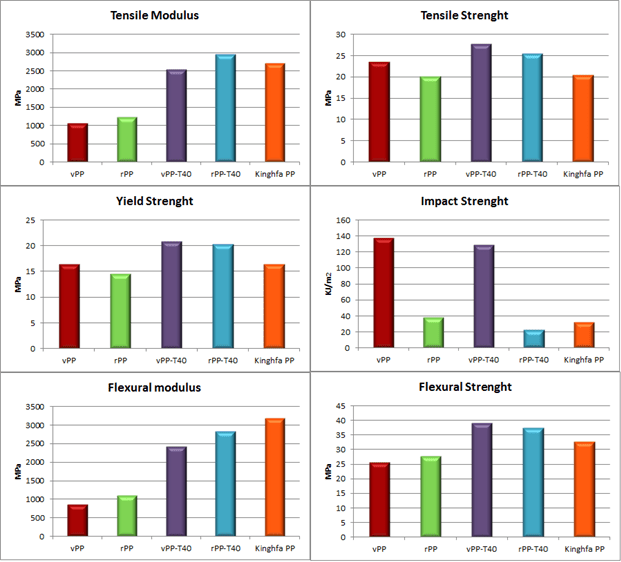

One of the most important applications of PP/Talc composites is the use in the automotive industry, especially the interior parts of the car such as the dashboard. Addition of PP-g-MA increases the properties of car parts made of PP/Talc composite. For example, the properties of polypropylene (PP), recycled polypropylene (rPP) and PP/graft/Talc and rPP/graft/Talc composites have been compared with commercial samples of PP/Talc composites (Kinghfa PP), with the same percentages of talc (Figure 9). The formulation of the mentioned samples is according to Table 1.

Table 1. Formulation of samples related to Figure 9

Figure 9 shows the mechanical properties of these samples. As can be seen, using PP-g-MA compatibilizer, even with rPP-based composites, similar properties can be achieved, or in many cases higher than commercial samples.

Fig. 9. Comparison of polypropylene/talc composite containing graft with commercial samples

Author: Emad Izadi Vasafi

References:

- Maddah, Hisham A. “Polypropylene as a promising plastic: A review.” Am. J. Polym. Sci 6.1 (2016): 1-11.

- Leong, Y. W., and Abu Bakar. “MB; Ishak, ZAM; Ariffin, A.; Pukánszky, B. Comparison of the mechanical properties and interfacial interactions between talc, kaolin, and calcium carbonate filled polypropylene composites.” J. Appl. Polym. Sci 91 (2004): 3315-3326.

- Hemmati, M., et al. “Effect of polypropylene–grafted–maleic anhydride compatibilizer on the physical properties of polypropylene/carbon nanotube composites.” Polymers and Polymer Composites 20.6 (2012): 559-566.

- Liu, Keyan, et al. “Effects of surface modification of talc on mechanical properties of polypropylene/talc composites.” AIP Conference Proceedings. Vol. 1713. No. 1. AIP Publishing LLC, 2016.

- Ammar, O., et al. “Talc as reinforcing filler in polypropylene compounds: effect on morphology and mechanical properties.” Polym. Sci 3.8 (2017).

- Alavi, M., et al. “Study of the rheological properties of polypropylene/talc/nanoclay ternary hybrid nano composites.” e-Polymers 10.1 (2010).

- Denac, Matjaž, Vojko Musil, and Ivan Šmit. “Polypropylene/talc/SEBS (SEBS-g-MA) composites. Part 2. Mechanical properties.” Composites Part A: applied science and manufacturing 36.9 (2005): 1282-1290.