Effects of Talc on mechanical properties of Polypropylene

Effects of Talc on mechanical properties of Polypropylene

Introduction

In the recent years, Polypropylene (PP) has found wide applications in different industries, including automotive, interior decoration, packing, fibers, etc. The main reason for this popularity is the high physical and chemical resistance and the relatively low cost of this polymer. The production of PP has reached more than 30 million tons in 2000.

Fig.1. Talc

Fig.1. Talc

Talc and its uses

Talc (Mg3Si4O10(OH)2) is a type of mineral whose plates include a layer or sheet of brucite between two sheets of silica that are connected by van der Waals force which allow them to slide on top of each other, and this mineral has little chemical activity. The majority role of talc is as a filler. Talc, can improve the stiffness of some products such as: polypropylene, vinyl, polyethylene, nylon, and poly ester.

Fig.2. An example of using talc and PP

Fig.2. An example of using talc and PP

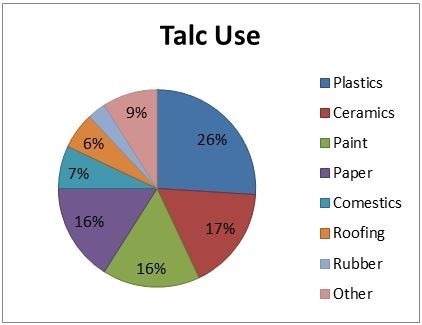

Powdered talc has a very shiny white color, which makes it an excellent filler in painting colors because it acts as a whitener and a color gloss at the same time. The low hardness of talc is beneficial; it causes less wear and tear on spray nozzles and other painting equipment. It is used the most in the polymer and plastic industries and the production of electric cables, because of its resistance to heat and electricity in the construction of laboratory table surfaces plus electrical distribution boards.

Fig.3. Applications of talc in different industries

Fig.3. Applications of talc in different industries

Effect of talc on mechanical properties

In the rest of this article, the effects of talc on polypropylene have been investigated and by diagrams and analyzing them, the positive role of talc on mechanical properties will be confirmed.

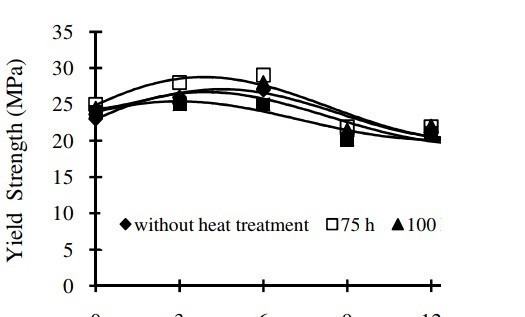

Fig.4. effect of adding talc to polypropylene in term of yield strength

Fig.4. effect of adding talc to polypropylene in term of yield strength

As it can be seen in the graph, the yield strength of the compound increased up to 6% with the addition of talc, and then it begins to decline. The increase in yield strength means that at that point of the percentage of talc used as a filler, there is a suitable adherence between the filler and the matrix. For this reason, it is resistant to higher pressures.

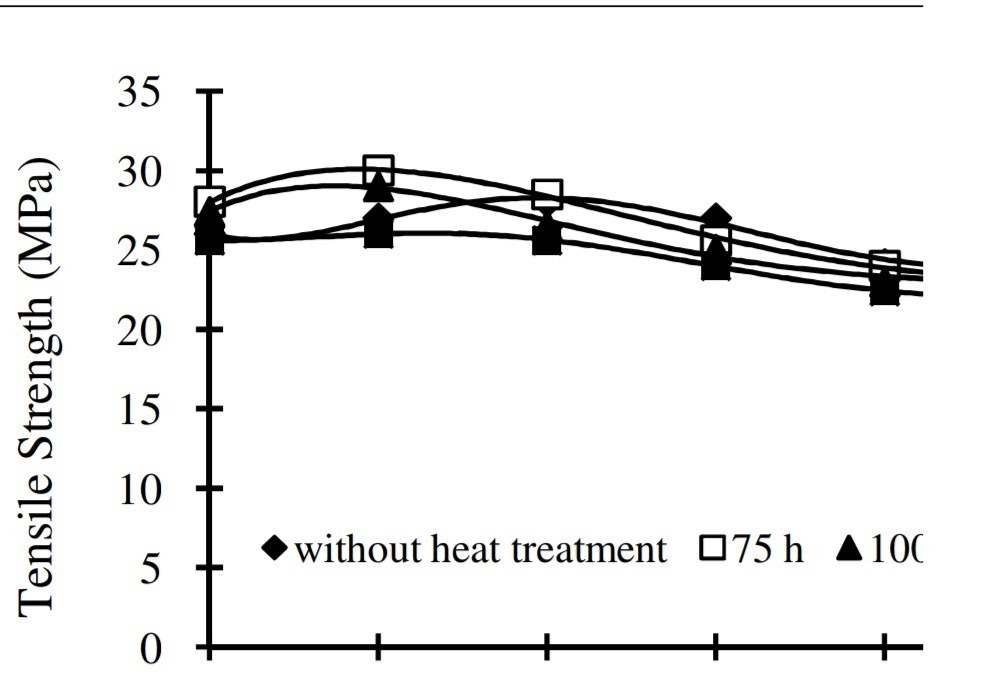

Fig.5. effect of adding talc to polypropylene in term of tensile strength

Fig.5. effect of adding talc to polypropylene in term of tensile strength

In the diagram, the highest tensile strength in talc amounts of about 3% happens. It should be noted that positive effects on mechanical properties occurred, when the fillers are well distributed in the matrix with the right proportions. For example, the maximum tensile strength occurs when 3% talc is used as a filler, so in this mass percentage in the microscopic space, the appropriate distribution of the filler in the matrix was seen.

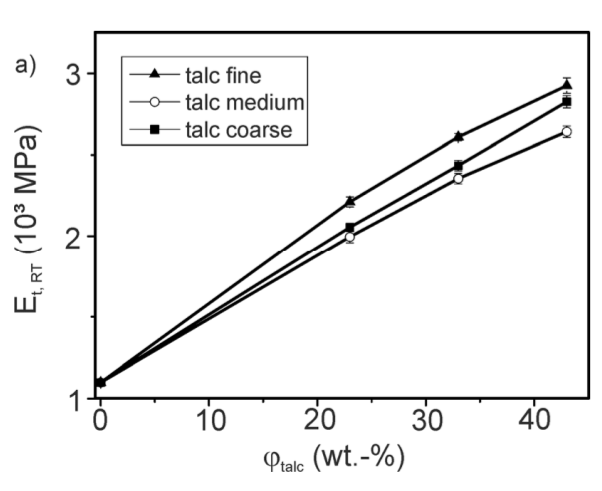

Fig.6. effect of adding talc to polypropylene in term of elasticity modulus

Fig.6. effect of adding talc to polypropylene in term of elasticity modulus

With the increase of talc, the elasticity modulus (Young’s modulus) increased significantly, which reached to 40%. If the Young’s modulus increases, it means that the filler particles are rigid and slow down the mobility of the compound. In conclusion, from the given diagram talc generally increases the modulus.

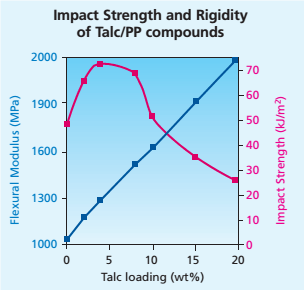

Fig.7. effect of adding talc to polypropylene in terms of flexural modulus, and impact strength

Fig.7. effect of adding talc to polypropylene in terms of flexural modulus, and impact strength

According to the above figure, it is evident that the flexural modulus increases with the increase of talc percentage. Also, using up to 5% talc led to increasing in impact strength, but after that the trend has changed. This measurement is assumed at constant temperature.

In short, adding talc to polypropylene leads to higher hardness, surface strength, and also improvement in flexural and tensile modulus.

Author: Emad Izadi Vasafi

References:

- Properties of polypropylene Talc Compounds with different talc particle size and loading J.shone, and Wolfgang Grellmann

- Effect of the Talc Filler Content on the Mechanical Properties of Polypropylene composites Lubomir Lapcik, Pavlina Jindrova, Barbora Lapcikova, Richard Tamblyn, Richard Greenwood, Neil Rowson

- Effects of Melt Temperature and Hold Pressure on the Tensile and Fatigue Properties of an Injection Molded Talc-Filled Polypropylene Yuanxin Zhou, P.K. Mallick