Antioxidant Masterbatch is one of the most important additives used in plastic manufacturing processes. Plastics are typically prone to aging when exposed to light, oxygen, and heat, which leads to changes such as reduced strength, stiffness, and flexibility, discoloration, surface scratching, and loss of clarity. Antioxidant masterbatch is added to the base polymer of products to prevent these problems from occurring.

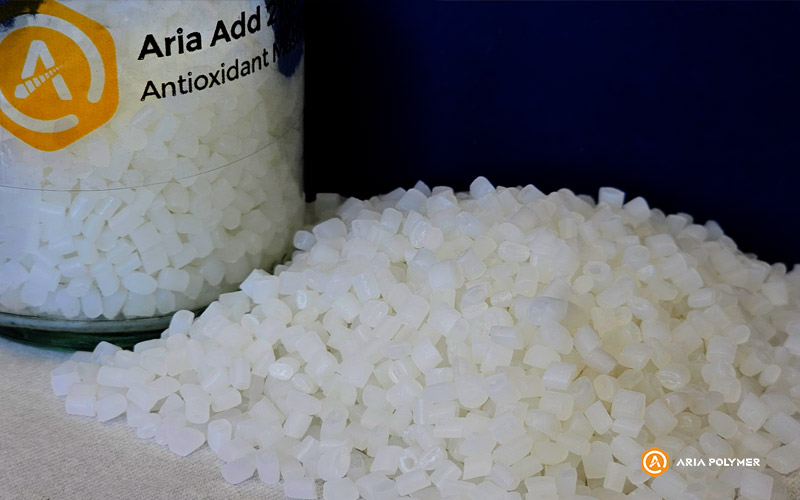

Aria Add 2130, 2135: PE-Based antioxidant masterbatch

For datasheets, please contact us through our Contact Page.

Stay informed about the latest Aria Polymer’s products by following our LinkedIn page.