Desiccant Masterbatch acts as a drying and water-absorbing agent, used to eliminate moisture in polymeric raw materials and recycled resins such as Polypropylene (PP) and Polyethylene (LDPE, LLDPE, and HDPE) during various production processes including blown film extrusion, injection molding, and blow molding. This masterbatch effectively addresses moisture-related issues that can occur during the production of plastic products, improving the final product quality and process efficiency.

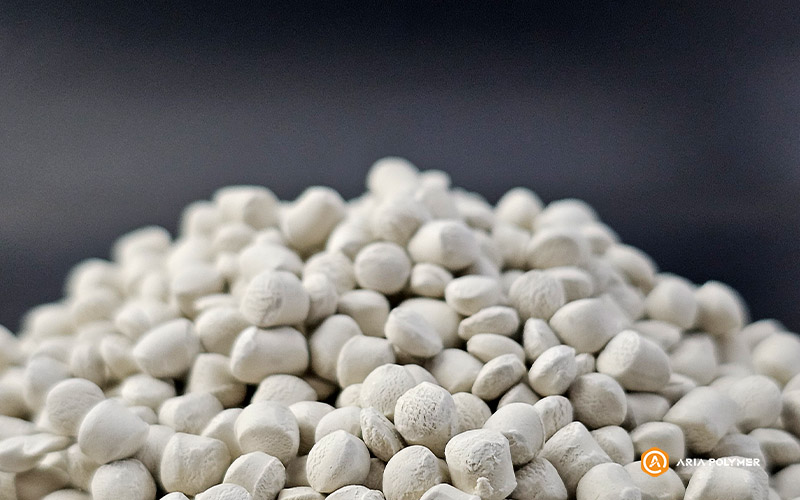

Aria Add 2180: Desiccant Masterbatch

For datasheets, please contact us through our Contact Page.

Stay informed about the latest Aria Polymer’s products by following our LinkedIn page.