Laser Print Modifier Masterbatch

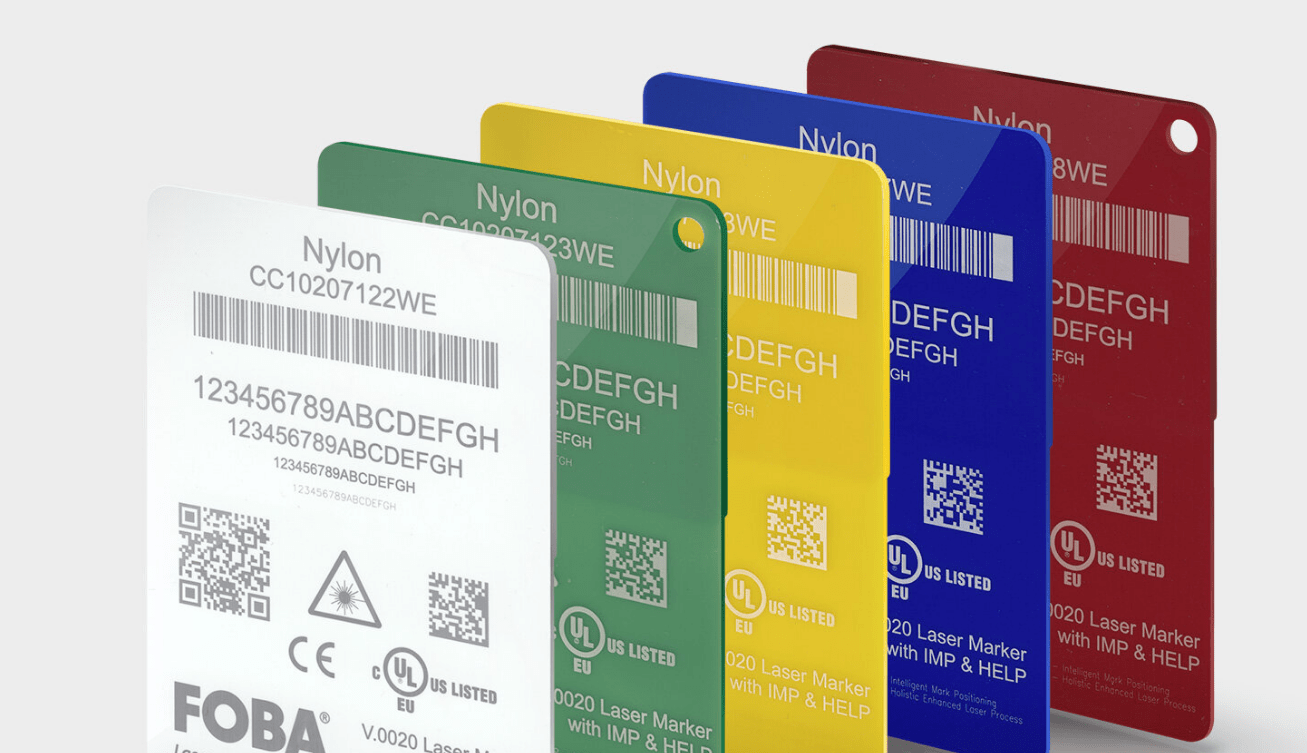

Aria Add 2100 is an Laser Marking Masterbatch concentrate by Aria Polymer Co. for absorb laser light with a wavelength of 1064 nm and achieve suitable marking contrast. In the numerous uses of plastic industry, marking capability on surfaces of plastic parts is needed by laser rays. These applications can be used to write the symptoms, beautify the surfaces especially for decorative applications, notes of production and other information. This property at caving the information for recognizing by barcode reader on some products such as wires, cables, pipes, electronic surfaces, food storage containers, medicines, and automobile parts (e.g. battery).

However, most of the polymers such as polyethylene and polypropylene do not able to absorb laser rays. As a result, marking by laser on these polymers permanently and with high resolution cannot happen. That is why they need additives to make their surfaces sensitive to laser. These additives lead to marking on plastic surfaces so that barcode readers can easily read the barcodes. Laser masterbatch which has suitable percentage of additives, has designed for making this ability for polyolefins. Adding from 2 to 3 % of the masterbatch can make symptoms readable. In addition, with color contrast without changes, it does not make any changes at other properties. It is worth mentioning, the symptoms which has made by laser on plastic surfaces, has advantages such as readability by barcode reader and high stability in comparison with inkjet prints.

Common methods of print on plastics

Common methods of print on plastics

- Ink-jet printing

- Code sticker

Disadvantages of these methods

They have limited life time and durability, and they are sensitive to environmental factors for degradation. This is why modifying before or even after printing usually is required. The mechanism of them is adhesion so polarity and hydrophily are two effecting factors.

But, the method of marking by laser is permanent and durable. Also, there is no need to modify the surface before printing. Most of the polymers are not sensitive to laser wave lengths so the cannot absorb the rays. In conclusion, there is a significant need to use an additive like metal oxide which can by absorbing laser rays, make changes in structure and make color contrasts. In fact, a reaction will happen by light or heat of the laser. Black and white pigments plus some fillers can be helpful at the process. High reading ability by barcode reader is one of the most remarkable benefits of laser printing method.

Laser Print Modifier Masterbatch of Aria Polymer Pishgam

Laser Print Modifier Masterbatch of Aria Polymer Pishgam

Aria Add 2100 as a laser marking masterbatch in granulate form contains additives which are able to enhance laser marking in plastics such as PE and PP.

Feel free to be in touch with us for purchase or any advice.

📲 +989120701632