Properties of polymers in packaging films

Properties of polymers in packaging films

Plastic films with a continuous polymeric thin layer have maximum thickness of 2.0 – 3.0 mm and high capability of flexibility. These films are used to separate layers, to act as a printable surface or as a barrier. Polymeric films have wide application in packaging films, labels, electrical equipment and porous membrane structures.

Plastic films have the largest amount of consumption compared to other plastics. In order to achieve the desired properties, it is very effective to use different additives such as slip agent, anti-block, processing aid, anti-static, UV absorber, anti-oxidants and kinds of pigments.

Types of polymers used in film production

Polymers used in the film production industry include different types of polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polystyrene, polyethylene terephthalate, polyamide, ethylene-vinyl alcohol (EVA) and polyvinylidene chloride. The produced films have properties corresponding to the base polymer. Depending on the use of polymer films, points such as permeability to water vapor and oxygen, tensile strength, maximum temperature of use, cost and processability are very important. In the following, each of the polymers used in the film industry and their characteristics have been introduced.

-

Polypropylene

- Good price, processability and good chemical compatibility with other materials.

- Good tensile strength and surface hardness.

- Improving transparency.

- Capability to add various pigments.

- Good moisture barrier

- Application in food bags, packaging and transparent labels.

Figure 1. Use of PP in packaging films [1]

Figure 1. Use of PP in packaging films [1]

-

Polyethylene

- Tear resistant.

- Good resistance to water vapor permeation.

- Lack of brittleness at low temperatures and suitable for packaging frozen products such as ice cream

- Low printability.

- High permeability to oxygen and solvents.

Figure 2. Use of PE in packaging films [2]

Figure 2. Use of PE in packaging films [2]

2.1. High density polyethylene (HDPE)

- Low production cost.

- Easy processing.

- Low melting point and relatively high melt flow index.

- Very high oil resistance.

- Poor resistance to oxygen.

- Application in the production of transportation and industrial bags.

Figure 3. HDPE Film [3

Figure 3. HDPE Film [3

2.2. Low density polyethylene (LDPE)

- High transparency and flexibility.

- Low production cost and easy processing.

- High resistance to tearing and impact.

- Low resistance to oil and scratches.

- Good barrier against moisture and permeability of oxygen, odor and gases.

- Suitable for film and coating.

Figure 4. Use of LDPE film [4]

Figure 4. Use of LDPE film [4]

-

Polyethylene terephthalate (PET)

- Low density, excellent dimensional stability and suitable printability.

- Low elongation and has the highest tensile strength among packaging polymers.

- High impact resistance and excellent resistance to oils.

- High melting point.

- Packaging items that require tensile strength or high temperature resistance, such as cheese, meat, and electronic components.

Figure 5. Application of PET film [5]

Figure 5. Application of PET film [5]

-

Polyamide (PA)

- High abrasion resistance, high notch resistance in continuous bending and oil resistance.

- Optical properties.

- Permeability against water vapor.

- High barrier against odors, oxygen, nitrogen and carbon dioxide and application in vacuum packaging of cheese and meat.

Figure 6. PA packaging films [6]

Figure 6. PA packaging films [6]

-

Polystyrene (PS)

- Rigid, stiff, brittle and impact resistant

- Transparency, easy coloring, suitable printing, polished.

- Excellent optical properties.

- Good chemical resistance against food acids and bases.

- Low resistance to many solvents and suitable for the production of liquid adhesives.

- Application in protection and packaging of dairy products and making some containers by injection molding method.

Figure 7. Polystyrene packaging films [7]

Figure 7. Polystyrene packaging films [7]

-

Ethylene Vinyl Alcohol (EVA)

- The most impermeable to oxygen.

- Strongly affected by water.

- Application in the packaging of agricultural chemicals and solving the problem of environmental pollution.

Figure 8. EVOH packaging films [8]

Figure 8. EVOH packaging films [8]

-

Polyvinyl chloride (PVC)

- Suitable optical properties and favorable dimensional stability.

- High impact strength and good scratch resistance.

- Low heat stability.

- Production process is more difficult compared to PP and PE.

- It is not possible to produce PVC film without using additives because it is hard and brittle.

- Permeability against moisture.

Figure 9. PVC packaging films [9]

Figure 9. PVC packaging films [9]

-

Polyvinylidene chloride (PVDC)

- Good resistance against oil

- Very low permeability to water and pure gases.

- High hardness and strength.

- Application in pharmaceutical and food packaging, production of single-layer and multi-layer films, as a cover.

Figure 10- Application of PVDC films [10]

Figure 10- Application of PVDC films [10]

In order to check and compare the properties of polymer films in more detail, Table 1 has been prepared.

Table 1. Comparison of polymers used in the film industry

| Polymer | Permeability properties against oxygen | Permeability properties against water vapor | Tensile strength | Strain strength | Maximum operating temperature |

| PP | 150 | 0.4 | Middle | Middle | 116 |

| HDPE | 110 | 0.3 | Middle | Middle | 100 |

| LLDPE | __ | __ | Low | High | 77 |

| LDPE | 480 | 1.2 | Low | High | 66 |

| PET | 5 | 1.3 | High | Low | 204 |

| PA | 3 | 25 | Middle | Middle | 177 |

| EVA | 0.02 | Water absorbent | __ | __ | __ |

| PVDC | 0.2 | 0.05 | __ | __ | __ |

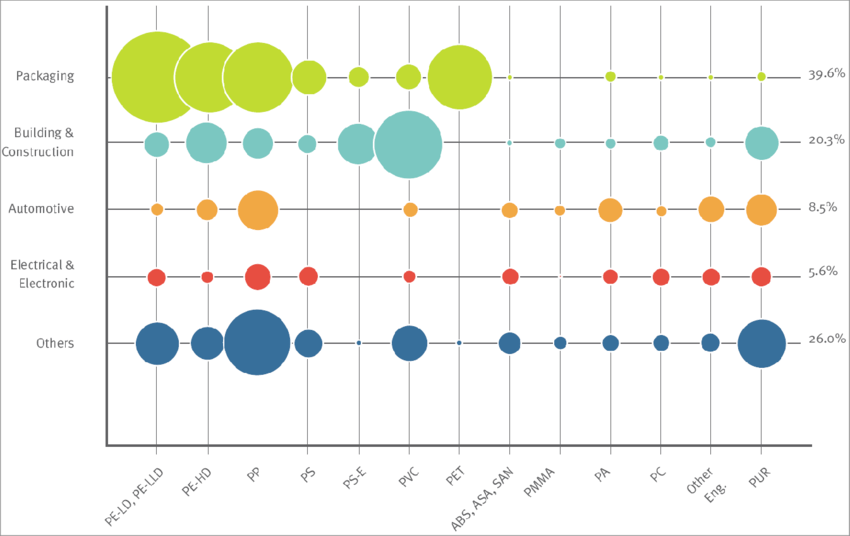

As seen in Figure 11, among the polymers used in the film industry, polypropylene and polyethylene, have a special place; because their structure is non-polar. Polarity affects many properties of matter such as melting point and solubility. For this reason, films prepared with polar structure have special features and applications.

Figure 11. The consumption of polymer films in different industries [11]

Figure 11. The consumption of polymer films in different industries [11]

References

[1]. poma.com.vn/en/the-difference-between-pe-film-and-pp-film.

[2]. http://baobinetviet.com/bat-mi-bi-quyet-thiet-ke-bao-bi-kem-thu-hut-khach-hang.

[4]. himachalwatcher.com/2014/12/27/himachal-encourages-off-season-vegetables-and-water-harvesting/

[6]. https://ku-oit.jp/assets/demoday2023/documents/presentation_06.pdf.

[7]. pngtree.com/freepng/polyethylene-and-polystyrene-packaging-for-food_7863520.html

[8]. europlas.com.vn/en-US/blog-1/understanding-evoh-plastic-food-packaging

[9]. www.la.lv/vairaki-latvijas-uznemumi-plano-attistit-eksportu-uz-namibiju

[10]. www.indianyellowpages.com/mumbai/neelam-global-pvt-ltd-nariman-point-mumbai-142935/