Protective coating material self-heals in 30 minutes when exposed to sunlight

Protective coating material self-heals in 30 minutes when exposed to sunlight

Researchers have developed a transparent protective coating material that can self-heal in 30 minutes when exposed to sunlight.

Excellent durability of automotive coatings is the most important issue in protecting a vehicle surface. In addition, protective coating materials

should be colorless and transparent so that the original color of the product can be seen.

However, it is difficult to provide a self-healing function while satisfying all of these conditions.

Materials with free molecular movement have high self-healing efficiency, but have low durability, whereas materials with high hardness and excellent

durability have remarkably poor self-healing performance.

The research team of Dr. Jin Chul Kim, Dr. Young il Park, and Dr. Ji-Eun Jeong of the Korea Research Institute of Chemical Technology (KRICT) has developed

a transparent coating material that satisfies all of the above conditions and has similar performance to that of commercial protective coating materials and can be self-healed

with only sunlight (particularly near infrared light in sunlight, in the wavelength range of 1,000 to 1,100 nm).

The research team of Dr. Jin Chul Kim, Dr. Young il Park, and Dr. Ji-Eun Jeong of the Korea Research Institute of Chemical Technology (KRICT) has developed

a transparent coating material that satisfies all of the above conditions and has similar performance to that of commercial protective coating materials and can be self-healed

with only sunlight (particularly near infrared light in sunlight, in the wavelength range of 1,000 to 1,100 nm).

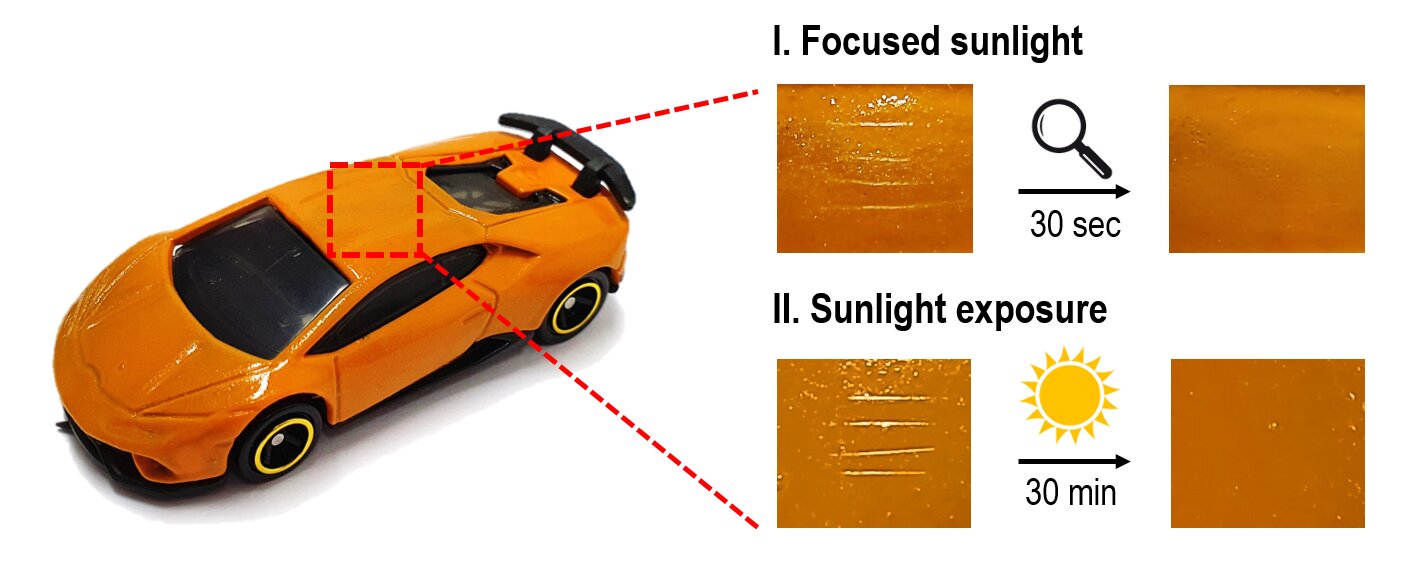

Using the developed self-healing protective material, surface scratches can heal in 30 minutes when exposed to sunlight. To demonstrate the self-healing performance of the developed coating material, the research team coated a laboratory-scale model car using a spray-coating machine. When the model car was exposed to midday sunlight for about 30 minutes, a scratch completely disappeared and the surface of the coating material was restored.

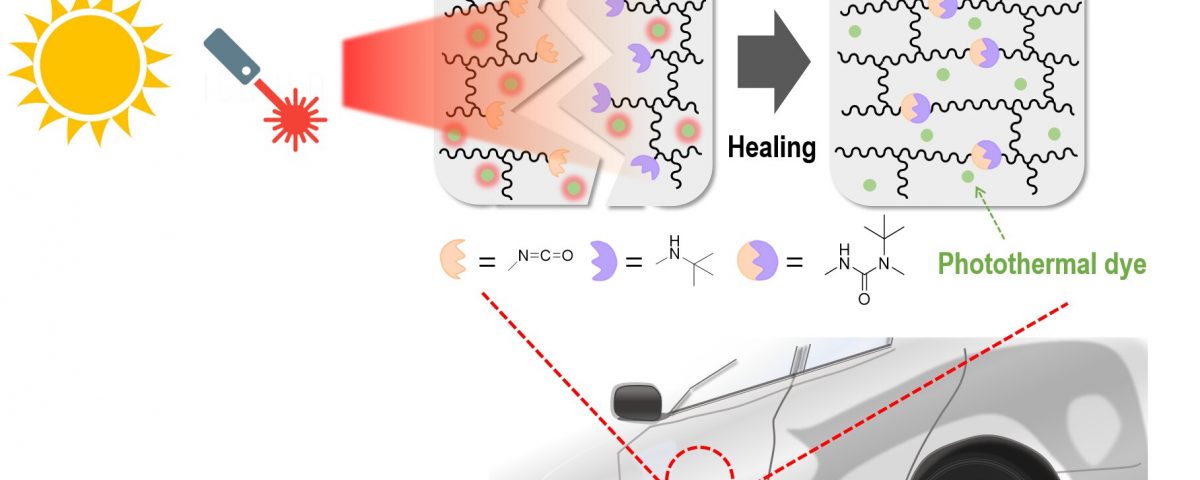

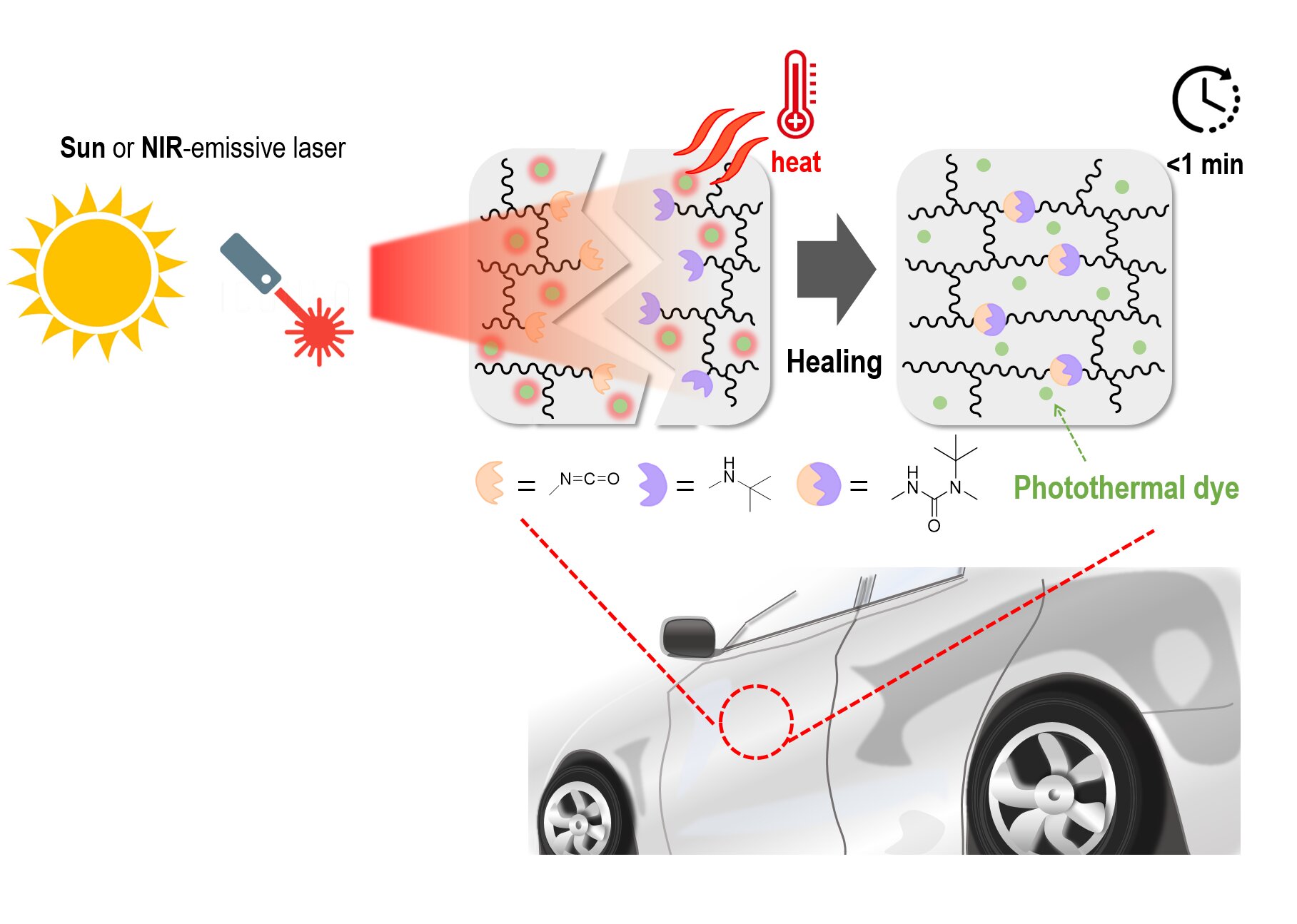

When sunlight is absorbed by the developed material, the surface temperature rises as light energy is converted into thermal energy. Subsequently, the increased surface temperature makes it possible to self-heal a surface scratch by repeating the dissociation and recombination of chemical bonds in the polymer structure.

To the existing commercial coating resin, the research team added a dynamic chemical bond (hindered urea structure) that can repeat the decomposition and recombination of the polymer structure, and mixed it with a transparent photothermal dye to induce dynamic chemical bonding actively upon exposure to sunlight.

Previous studies using photothermal dyes were mainly based on inorganic materials that are difficult to apply industrially as the coating material should be transparent. In addition, inorganic materials require a large amount of light energy to produce a photothermal effect.

The research team used transparent organic photothermal dyes that can absorb near-infrared light. Near-infrared light is a long-wavelength energy source that accounts for less than 10% of midday sunlight, and can thus circumvent excessive increase of the vehicle surface temperature. In addition, organic photothermal dyes have several advantages for commercialization: They do not affect the product color due to inherent colorlessness, easily blend with paints, and are inexpensive.

In the future, the developed self-healing material could be used as a coating material for transportation applications, electronic devices such as smartphones and computers, and building materials. In addition, it is expected to contribute to the realization of carbon neutrality by reducing the use of harmful organic solvents, which are generated in large amounts when repainting vehicles.

This research was published as the supplementary cover of the May 2022 issue of ACS Applied Polymer Materials.

Dr. Jin Chul Kim from KRICT, the research director, said, “The developed technology is a platform technology that synthesizes self-healing coating materials using both inexpensive commercial polymer materials and photothermal dyes. It is expected to be widely used not only in automotive clearcoats but also in various applications.”

More information: Da Hae Son et al, Fast, Localized, and Low-Energy Consumption Self-Healing of Automotive Clearcoats Using a Photothermal Effect Triggered by NIR Radiation, ACS Applied Polymer Materials (2022). DOI: 10.1021/acsapm.1c01768