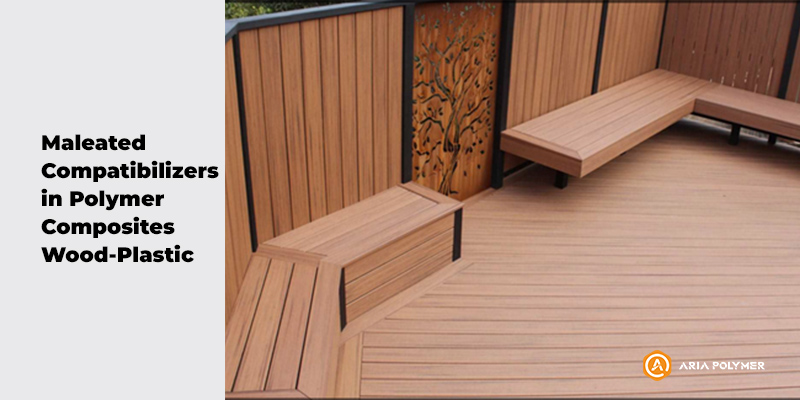

Wood-Plastic Composites, abbreviated as WPC, are a combination of wood fibers and at least one thermoplastic polymer. Initially, WPCs were developed as an industry for the consumption of recycled plastics and wood waste or sawdust. Some wood-plastic composite manufacturers still utilize recycled materials, while others use off-grade or unprocessed thermoplastics instead of, or in addition to, recycled materials.

Furthermore, in recent years, the volume of industrial wood waste generated by sectors such as building construction, furniture manufacturing, and the pulp and paper industries has increased significantly. This waste can be utilized in the synthesis of composite materials, leading to the production of sustainable, value-added products.

In this article, we examine the raw materials used in the wood-plastic composite industry, the role of existing compatibilizers and their impact on mechanical properties, water absorption, and other related properties. Furthermore, we explore some details regarding the interaction of compatibilizers with WPC components, such as fillers and lubricants, as well as the manufacturing process of wood-plastic composites.

Introduction

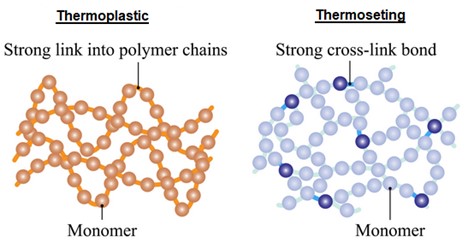

Wood-Plastic Composites (WPC) were established around the 1970s. These composites primarily consisted of wood particles and a thermoplastic polymer. Today, this concept has expanded, and the term WPC refers to any composite containing plant fibers and either thermoset or thermoplastic polymers.

The wood-plastic composite manufacturing industries are constantly evolving, seeking innovative solutions to address the challenges posed by the increasing environmental impacts of hazardous chemicals and excessive energy consumption. In some cases, the development of ‘Green Chemistry’ solutions has helped maximize raw material efficiency and minimize waste. The plant fiber component of these materials is considered a renewable resource with virtually unlimited availability. The popularity of wood-plastic composites stems from their high durability, low maintenance requirements, acceptable relative strength and stiffness, and lower cost compared to similar products. Other advantageous strengths include resistance to environmental factors such as biological degradation, particularly for outdoor applications where conventional wood products are unsuitable. Furthermore, unlike wood products, WPCs generally do not require surface treatments such as painting or other coatings.

Materials Used in WPC Manufacturing

Polyethylene

High-Density Polyethylene (HDPE) is stronger and stiffer than LDPE due to its higher crystallinity. It also exhibits greater shrinkage because of the formation of dense crystalline regions during the transition from a melt to a solid state. The tensile strength of HDPE is two to three times that of LDPE, and it possesses relatively good compressive strength. Since the crystallinity of HDPE is generally higher than that of LDPE, properties such as strength, modulus, density, shrinkage, creep resistance, abrasion resistance, and hardness are superior. In general, an increase in polyethylene density leads to enhanced abrasion resistance, chemical resistance, hardness, strength, and stiffness, while resulting in a decrease in gas and water permeability, thermal expansion, and impact resistance.

For this reason, HDPE is used in the thermoplastic fraction of the formulation for the production of certain wood-plastic composites

Polypropylene

Polypropylene (PP) offers several advantages over polyethylene. It is lighter, stronger, and stiffer; it exhibits improved creep resistance, as well as lower abrasion and friction. However, it is more brittle than polyethylene, especially at low temperatures. Polypropylene is utilized in various applications where it is combined with reinforcing agents through different methods. Generally, atactic polypropylene is used in the WPC industry. Polypropylenes are more susceptible to oxidation; consequently, PP requires significantly higher amounts of antioxidants and UV stabilizers compared to polyethylene. This is because oxygen absorption in polypropylene is much faster than in polyethylene. The primary reason lies in the chemical structure of polypropylene, which contains tertiary hydrogens; these make the formation of hydroperoxides much easier compared to polyethylene.

Wood Fibers

The wood filler used in wood-plastic composites (WPC) consists of ground and pulverized wood that has an appearance similar to flour. This filler typically has a mesh size of approximately 40 (roughly 400 micrometers). However, various grades of wood powder are classified into specific size ranges: 50–150 μm, 100–200 μm, 200–450 μm, and 250–700 μm. The use of cellulose fibers as an effective reinforcing filler enhances mechanical properties. Generally, increasing the wood particle size results in improved melt flow, reduced shrinkage, and a higher flexural modulus in the composite. Wood fibers typically have a bulk density of approximately 0.1 to 0.3 g/cm3, with an aspect ratio (the ratio of fiber length to thickness) usually ranging between 3:1 and 5:1. The specific gravity (density) of the wood substance itself is approximately 1.3 to 1.4 g/cm3. During ash content testing, wood typically leaves behind 0.25% to 0.50% mineral residue when incinerated at temperatures between 525∘C and 575∘C.

Maleated Compatibilizers

The poor interaction between non-polar (hydrophobic) polymers and polar (hydrophilic) natural fibers can be significantly enhanced by adding an adequate amount of maleic anhydride-grafted polyolefins (HDPE-g-MA or PP-g-MA). These chemically modified polymers, which feature a backbone compatible with the primary composite matrix, become entangled within the polymer matrix, while the maleic anhydride functional groups react with the hydroxyl groups of the wood’s cellulosic components. By utilizing these compatibilizers, also known as coupling agents, not only are interfacial adhesion and mechanical properties improved, but sensitivity to water absorption and biodegradation is also restricted to lower levels.

Fillers

Mineral materials, such as talc or calcium carbonate (CaCO3), are frequently used as fillers, primarily for economic reasons or with the objective of increasing the stiffness and mechanical resistance of the composite.

Lubricants

Lubricants are essential to prevent edge tearing (edge-cracking) in Wood-Plastic Composite (WPC) boards. Depending on the type of product and formulation, various internal and external lubricants are utilized in the WPC industry; these include polyolefin waxes, amide waxes (EBS), zinc stearate, lead stearate, calcium stearate, and silicone-based processing aids.

Typically, the amount of lubricant used in wood-plastic composites depends on the type of thermoplastic polymer and the wood fiber percentage. In HDPE-based composites, lubricants are added at approximately 4% to 5% by weight, whereas in PP-based composites, only 1% to 2% is used due to the polymer’s superior inherent flowability.

Other Additives

Wood fiber composites may contain additives for various functional purposes. Additives such as phenolic and phosphite-based antioxidants, ultraviolet (UV) stabilizers, slip agents, anti-blocking agents, colorants, pigments, flame retardants, biocides/insecticides (such as thiazolyl benzimidazoles), chemical foaming agents, and similar substances can be utilized within polymers or blends.

By using pigments, the need for secondary painting or finishing processes on the final products can be eliminated. Furthermore, UV stabilizers can reduce surface aging (weathering) of these polymer composites.

Properties improved by maleated compatibilizers

Polyolefin-based WPCs are a combination of plastic (non-polar) and wood (cellulosic fibers, which are polar in nature). Consequently, the adhesion between them is poor; the polar filler does not disperse well within the polymer matrix, resulting in a distinct two-phase state. Therefore, during impact, the composite cannot optimally transfer stress between the two phases. Compatibilizers improve the miscibility between cellulose fibers and the polymer matrix and facilitate fiber dispersion within the polyolefin matrix, thereby providing better flowability of the hot melt (even though compatibilizers generally increase the melt viscosity).

Maleated Polyolefins possess dual functional groups: a polyolefin segment capable of bonding with the polymer matrix, and a second group, maleic anhydride, which is capable of strong interaction with cellulose fibers at extrusion temperatures. Maleated polyolefins are typically prepared by grafting maleic anhydride onto the polymer backbone through radical reactions. Some data suggest that during the extrusion process, this maleic anhydride can develop enhanced covalent interactions with the hydroxyl groups of the cellulose, thereby anchoring the cellulose fibers to the thermoplastic polymer matrix. Maleated polyolefins are generally used at a concentration of 1% to 5% by weight in WPC formulations.

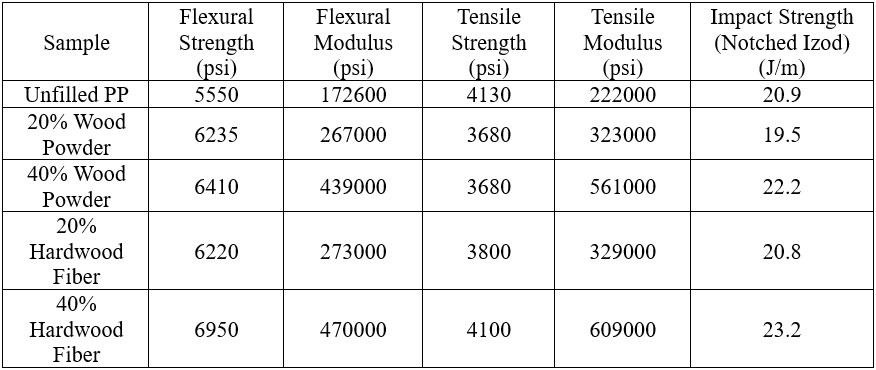

In polypropylene-based wood-plastic composites, adding 1% maleated polypropylene (MAPP) to a composition of 30% wood and 70% polypropylene results in a 15% increase in tensile strength. Increasing the amount of maleated polypropylene compatibilizer to 5% in the formulation leads to a 40% increase in the tensile strength of the final product. Furthermore, the tensile strength, flexural strength, and impact resistance of WPCs are significantly enhanced in the presence of maleated polypropylenes.

Compatibilizing agents, when applied under appropriate temperature conditions, minimum moisture levels, and in the absence of compounds that chemically hinder their bonding to the polymer matrix (such as metal-containing stearates), can significantly enhance the mechanical properties of WPCs. They can increase impact resistance by two to three times and reduce degradation and water absorption by two to four times (depending on the duration of the immersion test). Furthermore, they increase the density and, consequently, the resistance of the WPC to environmental factors, including oxidation and other degradation processes.

It must be kept in mind that maleated polyolefins can slowly react with atmospheric moisture during storage, forming free acids. As a result, the chemical reactivity of these coupling agents is reduced. Therefore, care must be taken to store maleated polyolefins in a dry environment. Other properties of wood-plastic composites, such as the glass transition temperature (Tg), typically show no change in the presence of maleated polymers, or they may experience a slight decrease.

Compatibilizing agents must affect the rheological behavior of the WPC hot melt in a manner distinct from that of lubricants and plasticizers. Generally, it is expected that the bonding between wood fibers and the maleated polyolefin will increase the shear viscosity, whereas lubricants decrease viscosity. In practice, describing the rheological effect of the compatibilizer on the WPC melt is complex due to wall slip and entrance pressure drop. Furthermore, the impact of the compatibilizer on the WPC composite’s rheology depends on the molecular weight of the polymer matrix, the molecular weight distribution (MWD), and the molecular characteristics of the compatibilizer itself. On the other hand, the cellulose fibers also increase the hot melt viscosity of the plastic.

The Compatibilizing Effect on Water Absorption in WPC

Compatibilizing agents often improve the density of WPCs. For example, by adding up to 3% by weight of a compatibilizer to an HDPE-based composite containing 60% wood filler, the composite density increases from 1.13 to 1.20 g/cm³. Consequently, these composites exhibit lower water absorption.

Lubricants Compatible and Incompatible with Maleated Compatibilizers

Maleated polyolefins and metal stearate lubricants exert contradictory effects in wood-plastic composites. Zinc stearate consistently reduces the strength and stiffness of WPCs compared to non-metallic lubricants. Essentially, adding 2% zinc stearate to a WPC neutralizes the gains in strength and stiffness achieved through the use of compatibilizers. In other words, the flexural strength and modulus revert to the values observed in the absence of compatibilizing agents. Therefore, zinc stearate eliminates the beneficial effects of maleated polymers on wood-plastic composites.

It has also been established that maleic acid, which forms from the grafted maleic anhydride during the process in the presence of moisture, reacts with zinc stearate. This reaction is thermodynamically more favorable than the bonding of the maleated polyolefin to the cellulose fibers and essentially eliminates the effect of the coupling agent from the final WPC product.

Non-metallic lubricants used in conjunction with maleated polyolefins often do not inherently improve the properties of the resulting WPC; however, unlike metal-containing lubricants, they do not lead to the functional impairment of the maleated polyolefins in the final product.

Equipment Used and Process Requirements

Manufacturing methods for wood-plastic composites include extrusion, injection molding, and compression molding. It has been established that the presence of moisture within the cellulosic fibers leads to steam formation during the compounding and extrusion processes. This increases the porosity of the final product and reduces its density, accelerates the oxidation of the hot melt during processing, and results in a weaker, less durable final product. As a result, it is necessary to remove moisture from cellulose fibers before mixing them with thermoplastic polymer.

Optimization and Conclusion

Depending on the raw materials, additives, and selected processing techniques, many of the advantages of WPCs stem primarily from the low density and high specific strength of plant fibers, their non-abrasive nature, biodegradability, recyclability, and low cost. Considering the huge variety of polymers available in the market, even with the same basic composition and the specific characteristics of each type of wood fiber, optimizing composites for a specific application requires a detailed study of the selected components, before and after mixing and processing as composite materials, in order to achieve sufficient final physical, chemical and mechanical properties.

References