In this article, we will explore polymer additives, what they are, their applications, and two important types of them. We’ve written it in simple words, avoiding heavy polymer jargon. Let’s delve into it:

What Is Polymer Additive?

In simple words, polymer additives are special materials that are incorporated into the base polymer to add new properties or improve existing ones in the final product.

For example, imagine you are a manufacturer of traffic equipment. The base polymer for producing these items is polyethylene (PE). However, you cannot make them using only PE, because polymers are sensitive to climate and long-term sunlight exposure. Over time, they may undergo physical changes, such as discoloration or degradation.

To prevent this, anti-UV masterbatch is added to the base PE. This additive protects the material against sunlight and helps the product maintain its quality and durability for a longer period. Here anti-UV masterbatch is considered as a polymer additive.

Obviously, polymer additives aren’t limited to just masterbatches, they include a wide range of polymer-based materials.

For example, in manufacturing certain automobile parts, polypropylene (PP) is often combined with glass fibers. However, because PP has a nonpolar structure and glass fiber has a polar structure, they are naturally incompatible. This incompatibility prevents the glass fibers from being evenly distributed within the polymer matrix, which reduces the strength and performance of the final composite.

To solve this problem, a specialized additive called a PP coupling agent (PP compatibilizer) is used. This material acts as an intermediate, enabling polypropylene and glass fibers to bond uniformly. As a result, the composite achieves improved mechanical properties. In this case, the PP compatibilizer is considered a polymer additive.

In conclusion, any material incorporated into a base polymer to add or modify certain properties is considered a polymer additive. These additives are typically used in small amounts, usually less than 5% of the total formulation, yet they play a crucial role in enhancing the performance and durability of the final product.

Applications of Polymer Additives

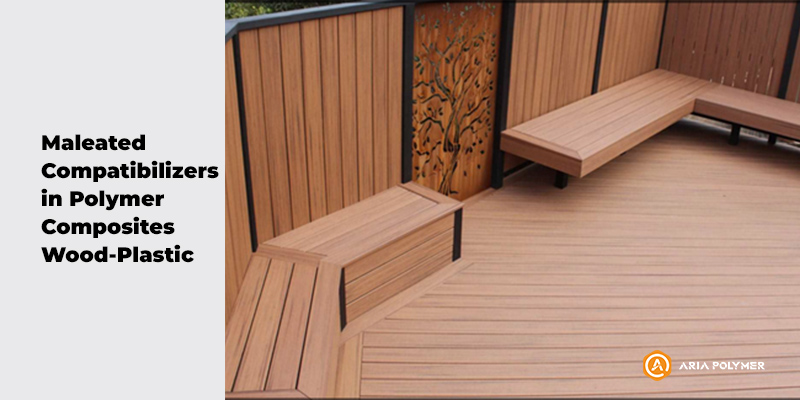

Practically, whenever a product is manufactured using polymers, polymer additives are always involved. We have already mentioned two applications, but their use extends far beyond that. Polymer additives are widely applied in compounding, home appliances, electronics, WPC (wood–plastic composites), tie-layer adhesives, biodegradable films, and many other industries.

Additive Masterbatch

As mentioned earlier, additive masterbatch is a type of polymer additive. Masterbatches themselves include a wide range of products, and each one creates a specific effect in the final product. For example, black masterbatch is a type of additive masterbatch that provides a consistent black color in the final plastic product.

Here are Aria Polymer’s additive masterbatches. For technical specifications, click on the related item:

Coupling Agent

Coupling Agents (Compatibilizers) are another important type of polymer additive. They enable two otherwise incompatible materials (such as different polymers, or a polymer with a filler) to bond together in a product.

At Aria Polymer, we manufacture the following compatibilizers. For technical specifications, click on the related item:

Tips for Purchasing Polymer Additives

Purchasing polymer additives is a specialized task and requires considering several factors, such as MFI and other properties, to select the additive that best suits your product. For example, you may need to test several specific compatibilizers on your raw materials to ensure the final product meets the desired performance.

Polymer manufacturers typically request a few kilograms of a new additive as a sample for testing before placing a bulk order. Aria Polymer provides free samples of its products for testing purposes. Please feel free to contact us if you need any samples.

Final Words

Aria Polymer Pishgam is a manufacturer of various polymer additives, including additive masterbatches and compatibilizers. For orders, price inquiries, technical consultation, and more, please get in touch with us through the contact options available on our Contact Us page.