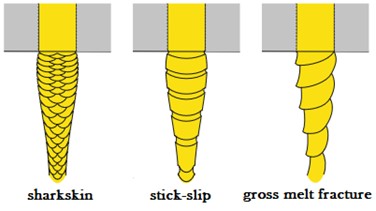

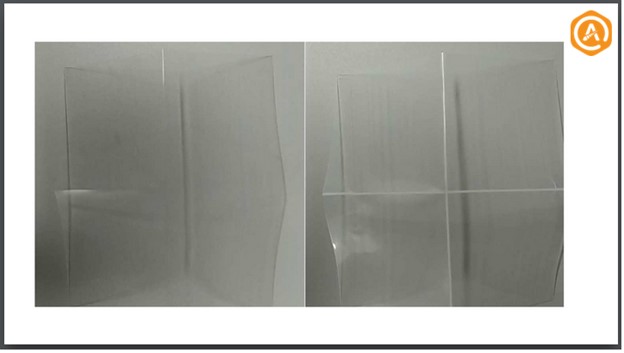

In polymer extrusion and other commercial polymer processing methods such as fiber spinning, film blowing, blow molding, stretching, and film casting, polymer melts exiting the die often exhibit surface flow instabilities that manifest as distortion in the extruded product. Three types of melt fracture resulting from flow instability manifest themselves in the form of sharkskin distortions, stick-slip, and gross melt fracture. Periodic distortions with a small amplitude on the surface of the polymer melt are of the shark skin type, and severe and irregular distortions at higher flow rates are of the Gross melt fracture type. In Stick-Slip type distortions, the melt movement is constantly characterized by sticking to the extruder wall and releasing. Figure 1 shows the types of distortions resulting from flow instability in the molten polymer extruded from the extruder.

In extrusion processes, distortion in the polymer melt is observed when the volumetric flow rate exceeds a certain (critical) value. The intensity of distortions (amplitude and frequency or irregularity) increases with increasing flow rate.

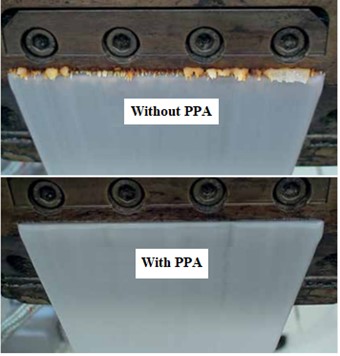

To overcome these problems and make the processes economically feasible, polymer processing aids (PPAs) are often used. The processing aids can eliminate sharkskin and stick-slip melt fractures or delay them to higher flow rates. The result of using processing aids is increased productivity, reduced energy costs, while maintaining product quality.

Decades of research on processing aids are examined in this section. The discussion focuses on how these materials perform in eliminating melt fracture, which clarifies their function in improving polymer processability and mitigating flow instabilities.

Types of materials used as processing aids

Fluoropolymer-based additives were the first processing aids used, initially in polyolefin extrusion. Silicone-based polymers are also frequently used as processing aids. Other processing aids used include stearates, hyperbranched polyethylene, and various polymer blends. Recently, boron nitride has also been employed for this purpose.

Fluoropolymer-based processing aids

The most relevant commercial example is the use of fluoropolymer-based processes to eliminate sharkskin melt fracture in linear low-density polyethylene (LLDPE). One type of fluoropolymer used as additive for LLDPE is a copolymer of vinylidene fluoride (VF2) and hexafluoropropylene. In vinylidene fluoride, the hydrogens become acidic due to the electronegativity of fluorine. The dipole moment created by this monomer causes it to interact with oxides on the surface of the steel (such as the cylinder and screw in an extruder). Hexafluoropropylene also has a weak interaction with polyethylene (nonpolar), and for this reason, it reduces the adhesion between polyethylene and vinylidene fluoride.

In common industrial applications, fluoropolymers are added to the polymer in small amounts, they are highly immiscible with polyolefins, and the resulting material is a dilute two-phase mixture. Therefore, after being combined with the polymer, they exit from the polymer matrix and settle on the surface, reducing friction with the metal.

Besides eliminating certain melt instabilities in the extrudate, fluoropolymers offer several advantages. These include reducing gel formation, minimizing die build-up and overflow, shortening the color-change induction time, and partially eliminating draw resonance in processes like fiber spinning, film casting, and film blowing.

Stearates

Calcium and zinc stearates are used as acid scavengers in the production of several commercial resins, including linear and long-chain branched polyethylene. strong evidence exists indicating that stearates in low-density polyethylene copolymers with a low degree of long-chain branching increase slippage and help reduce instability (fracture) in the molten polymer.

High concentrations of stearates may interact with processing aids and other additives in certain process conditions. Many additives for polyolefins, such as UV stabilizers, antioxidants, antistatic agents, and slip agents, have little interaction with processing aids. However, anti-blocks and fillers added to films may reduce the effectiveness of processing aids.

Silicon-based processing aid

Silicone-based polymers and polydimethylsiloxane (PDMS) oils have been used as polymer processing aids. Due to their low surface tension, these fluids migrate to polymer surfaces, which reduces friction. High-molecular-weight PDMS, which is solid at room temperature, has shown effectiveness in the extrusion of LLDPE and polypropylene (PP). Adding these can significantly reduce the surface roughness of extruded polymers.

Hyper-branched polymers

Addition of small amounts of hyper-branched hexa-decanoate terminated polyesters (HBPs), significantly improved fiber extrusion and film blowing processing of LLDPE. Sharkskin elimination and substantial reduction in extruder power were achieved on addition of only 0.5% of HBP.

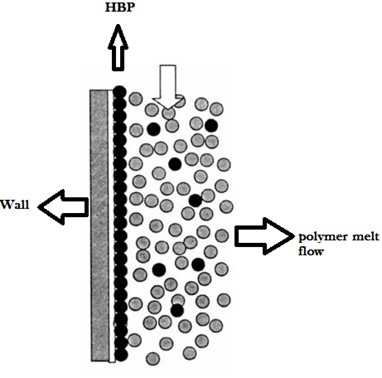

Hyper-branched polymers tendency to migrate to the wall surfaces, where it preferentially accumulated forming a phase-separated layer. The mechanism of fracture elimination by HBP was advocated to arise from either the reduced viscosity or the interfacial slip. in result HBP can migrate to the die surface and form a lubricating layer promoting extrudate slippage, reducing pressure drop and shear stresses and thus improving extrudate distortion.

Boron nitride–based processing aids

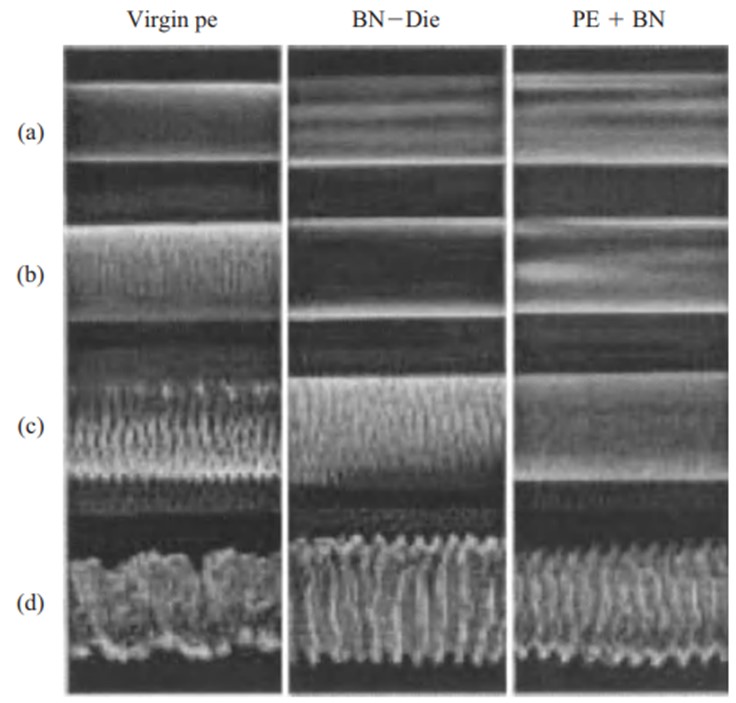

Boron nitride is a foam nucleating agent, and when added to the polymer melt can act as a very effective processing aid. Researchers discovered that the use of BN may eliminate gross melt fracture phenomena in the extrusion of fluoroelastomers and polyolefins.

Even though the use of small amounts of BN (typically up to 1 wt%) into polyethylene has practically no effect on their flow curves, it has been found to eliminate sharkskin and stick-slip melt fracture in the extrusion of LLDPE. Once in the gross melt fracture regime, the presence of BN may eliminate gross distortions, although it fails in eliminating surface distortions at such high rates.

Further experiments have shown that the maximal shear rate yielding a smooth extrudate is sensitive to the BN content. In other words, the use of BN not only can eliminate surface melt fracture but can also delay the gross melt fracture at high shear rates.

Influence of Using processing aids

Influence of using processing aids in conventional polymer processing methods:

Blown film extrusion

- Reduce die build-up

- Reduce gel formation

- Higher throughput

- Improved operation at lower processing temperatures and reduced degradation

- Lower operating pressures and amperage draw—increased output, energy savings

Cast film

- will delay the onset of deposition at the die exit

- provide significant productivity improvements

Pipe extrusion

- Reduction of die build-up

- Reduction of back pressure

- Reduction in processing temperatures

- Higher output

- Improved surface appearance of pipe

Conclusion

For any melt-processable thermoplastic polymer composition, there exists a critical shear rate above which the surface of the extrudate becomes rough or distorted and below which the extrudate will be smooth.

when a polymer is melt processed above a critical shear rate and can cause the surface of the extrudate to exhibit melt defects such as melt fracture, surface roughness, edge tear and sharkskin. A common melt defect is a rough surface on the extrudate, and is referred to as melt fracture. Melt fracture is primarily a function of the rheology of the polymer and the temperature and speed at which the polymer is processed.

In order to alleviate the problems of melt defects it is well known to add processing aids to polymeric materials. The processing aids are believed to function by forming a dynamic coating on the processing equipment and producing interfacial slip between the processing equipment and the polymeric material. Interfacial slip in this instance is defined as the reduction of surface tension, and subsequently shear stress, between the polymer melt and the processing equipment. Processing aids are known to improve processability and eliminate melt defects in thermoplastic polymers.

Final Words

Aria Polymer is a manufacturer of various polymer additives, including additive masterbatches, compatibilizers, and tie layer adhesives. For orders, price inquiries, technical consultation, and more, please get in touch with us through the contact options available on our Contact Us page.

Stay informed about the latest Aria Polymer’s products by following our LinkedIn page.

Authors